Understanding Asbestos: A Hidden Danger

Asbestos, a naturally occurring mineral known for its heat resistance and durability, has been used in various industries for decades. However, what many don’t realize is that asbestos poses a severe health risk when its fibers are released into the air and inhaled. These tiny fibers can lodge themselves in the lungs, leading to serious health issues such as lung cancer and mesothelioma.

Despite asbestos being banned in many countries now, older buildings and structures may still contain this hazardous material. The hidden danger of asbestos lies in its microscopic fibers that can easily become airborne during renovations, demolitions, or any activities that disturb asbestos-containing materials. This is where proper asbestos remediation becomes crucial to protect the health of individuals.

Identifying asbestos-containing materials is the first step in a remediation process. Specialized professionals need to assess the situation and determine the best course of action to safely remove or contain the asbestos. One integral part of effective asbestos remediation is the use of air blowers to control the spread of asbestos fibers during the remediation process.

When considering the health risks associated with asbestos exposure, it becomes evident why proper asbestos remediation is essential. By understanding the dangers posed by this hidden threat and the importance of addressing it promptly and effectively, we can safeguard the well-being of individuals and communities.

The Importance of Asbestos Remediation

Asbestos remediation is not just about complying with regulations; it’s about protecting lives. The consequences of ignoring the presence of asbestos or attempting amateur removal can be devastating. Proper remediation ensures that asbestos is handled safely, minimizing the risk of exposure and subsequent health issues.

The significance of asbestos remediation becomes even more pronounced in older buildings where asbestos was commonly used in construction materials. In these cases, regular inspections and timely remediation efforts are crucial to prevent the release of asbestos fibers into the environment. This proactive approach helps maintain a safe and healthy living or working space for all occupants.

An effective asbestos remediation strategy encompasses thorough assessment, careful planning, and meticulous execution. Professionals trained in handling asbestos removal and containment are equipped to manage the process safely and efficiently. By prioritizing the importance of asbestos remediation, we prioritize the well-being of those who could be exposed to this hazardous material.

Whether it’s a residential property, a commercial building, or an industrial site, investing in asbestos remediation is an investment in long-term health and safety. By addressing asbestos hazards proactively, we create healthier environments and contribute to the overall well-being of individuals and communities.

Introducing Air Blowers in Remediation Processes

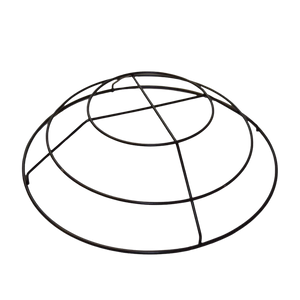

Air blowers play a crucial role in asbestos remediation by controlling the movement of air within a containment area. During asbestos removal or enclosure, air blowers are used to create negative air pressure, ensuring that any disturbed asbestos fibers remain contained within the work area. This containment strategy prevents the spread of asbestos particles to other parts of the building or the outdoor environment.

In remediation processes, air blowers, often equipped with HEPA filters, help in ventilating the workspace by continuously circulating and filtering the air. This constant air movement reduces the concentration of airborne asbestos fibers, making the environment safer for workers and preventing contamination of uncontaminated areas. Properly placed air blowers ensure that the air is effectively purified and harmful fibers are contained.

The use of air blowers in asbestos remediation exemplifies the integration of technology and safety measures to protect individuals from the health risks associated with asbestos exposure. By incorporating air blowers into remediation processes, professionals can work more efficiently and securely, minimizing the chances of airborne fiber dispersion and ensuring a controlled remediation environment.

As part of a comprehensive asbestos remediation plan, air blowers are essential tools that aid in maintaining a safe work environment for both remediation workers and occupants of the building. Their role in containing and controlling the movement of asbestos fibers demonstrates the commitment to safety and precision required in handling hazardous materials like asbestos.

How Air Blowers Help in Asbestos Containment

When it comes to asbestos containment, the strategic placement of air blowers is crucial. By setting up containment barriers and using air blowers in specific configurations, remediation professionals can effectively control the airflow and direction within the work area. This careful control prevents the escape of airborne asbestos fibers, maintaining a secure environment for remediation activities.

Air blowers enhance the containment process by creating airflow patterns that prevent the migration of asbestos fibers beyond designated work zones. By establishing a negative pressure environment with the help of air blowers, the movement of contaminated air out of the containment area is minimized, reducing the risk of cross-contamination and ensuring that the work environment remains safe and controlled.

In addition to containment, air blowers also aid in maintaining the integrity of the containment barriers by keeping them under negative pressure. This continuous airflow generated by the blowers helps to sustain the containment structure, preventing breaches that could compromise the safety of the remediation process. The coordinated efforts of air blowers and containment barriers are instrumental in achieving successful asbestos containment.

Types of Air Blowers Used in Asbestos Remediation

Several types of air blowers are employed in asbestos remediation projects, each serving specific purposes based on the scale and requirements of the task. High-efficiency particulate air (HEPA) filtration blowers are commonly used to maintain clean, breathable air by capturing tiny asbestos particles and preventing their release outside the containment area.

Negative air machines, equipped with HEPA filters, create negative pressure environments to control the spread of contaminants like asbestos fibers. By continuously drawing air through HEPA filtration, these machines ensure that the air released back into the environment is free from asbestos debris, maintaining a safe working environment during remediation activities.

Industrial-strength axial fans are also utilized in asbestos remediation to facilitate air movement within containment areas. These powerful fans are capable of generating high-volume airflow, allowing for efficient ventilation and filtration of air contaminated with asbestos particles. Their robust design and airflow capacity make them indispensable tools in large-scale asbestos removal projects.

Safety Measures When Operating Air Blowers in Asbestos Environments

Ensuring the proper operation of air blowers in asbestos environments is essential to maintain a safe workspace and prevent the spread of hazardous asbestos fibers. Before starting remediation work, it’s imperative to inspect the air blowers for any damage or malfunctions that could compromise their performance during the remediation process.

Proper training in the use of air blowers is crucial for remediation workers to handle and position the equipment correctly. Understanding the airflow requirements, positioning guidelines, and maintenance procedures of air blowers ensures their effective operation in containing asbestos fibers and maintaining a controlled work environment.

Regular monitoring of air blower functions and airflow patterns is necessary throughout the remediation process to verify their effectiveness in containing asbestos particles. Adjustments to airflow direction, blower speed, or filter conditions may be required to optimize containment efforts and minimize the risk of fiber dispersion.

Implementing stringent safety protocols, including wearing appropriate personal protective equipment (PPE) and following established containment procedures, is paramount when operating air blowers in asbestos environments. By adhering to safety guidelines and best practices, remediation professionals can mitigate risks associated with asbestos exposure and ensure a safer work environment for everyone involved.