"Welcome to FR Fire Restoration: Engineered for Recovery, Built on Legacy. At Mastercraft USA, we’ve witnessed how wildfires, like the recent events in California, have devastated communities and challenged professionals on the front lines. Since 1946, when Harry Goldberg founded our company with a mission to empower experts with durable, effective tools, we’ve led the industrial solutions market for over 76 years. Today, we introduce the FR Fire Restoration— a line of specialty industrial vacuums designed to tackle the challenges of fire restoration, blending the best of our expertise to deliver results where they’re needed most. For contractors rebuilding, firefighters protecting, and cleaning professionals restoring, this is more than a tool: it’s a commitment to recovery, backed by our legacy of excellence."

The Challenges of a Large-Scale Fire: From Start to Aftermath

"But to understand the value of our solutions, we must first explore the problems that arise in a large-scale fire—from its onset to its aftermath—and the health risks that impact both communities and the specialized personnel who respond."

The Start: Rapid Spread and Immediate Damage

A massive fire, like a wildfire or urban blaze, begins with a volatile mix of heat, fuel, and oxygen spiraling out of control. Initial challenges include:

- Rapid Spread: Combustible materials (wood, synthetics, gas) fuel flames that can overwhelm firefighters’ containment efforts.

- Dense Smoke: Combustion produces smoke laden with fine particles and toxic gases, reducing visibility and complicating evacuations.

- Structural Damage: Extreme heat weakens buildings, melts plastics, and compromises HVAC systems, leaving behind hazardous residues like soot and ash.

Health Impact:

- Community: Smoke inhalation causes respiratory irritation, coughing, and, in severe cases, acute lung damage.

- Personnel (Firefighters): Prolonged exposure to carbon monoxide (CO) and fine particles (PM2.5) increases risks of asphyxiation and chronic respiratory conditions.

During the Fire: Contamination and Secondary Risks

As the fire progresses, additional issues emerge:

- Toxic Material Release: Synthetic materials (furniture, carpets, plastics) emit Volatile Organic Compounds (VOCs), benzene, and formaldehyde.

- Structural Collapse: Weakened buildings release lead dust, asbestos, and other carcinogens when they crumble or are demolished.

- Reignition Risk: Soot and ash deposits can reignite if not properly managed.

Health Impact:

- Community: Exposure to VOCs and carcinogenic particles can cause headaches, nausea, and long-term cancer risks.

- Personnel: Risks of burns, gas poisoning, and physical injuries rise while working in unstable environments.

The Aftermath: Focus on Hazardous Residues

Once the fire is extinguished, the aftermath reveals a minefield of hazardous residues requiring specialized handling. These include:

- Soot and Fine Ash: Formed from black carbon and ultrafine particles (PM2.5 and smaller), these residues cling to surfaces, infiltrate HVAC systems, and linger in the air, heightening reignition and cross-contamination risks.

- Heavy Metals: Lead (from old paint or pipes), mercury (from thermometers or fluorescents), and cadmium (from batteries or burnt plastics) release as dust or mix with debris. Inhalation or prolonged contact can cause neurological, kidney, or cancer damage.

- Asbestos Fibers: Found in older buildings, heat fragments asbestos into microscopic fibers that lodge in lungs when inhaled, leading to mesothelioma or pulmonary fibrosis years later.

- Volatile Organic Compounds (VOCs): Derived from burnt plastics, adhesives, and coatings—like benzene (carcinogenic) and toluene (neurotoxic)—these persist in air and on surfaces post-fire.

- Extinguishing Chemical Residues: Firefighting foams (PFAS) and contaminated water introduce “forever chemicals” that leach into soil and groundwater, impacting community health long-term.

- Post-Water Mold: Water used to douse flames creates damp conditions, spawning toxic mold spores (e.g., Stachybotrys) that trigger allergies, asthma, and respiratory issues.

- Dense Debris: Metal, glass, and concrete remnants mixed with contaminants demand robust tools for safe handling.

Health Impact:

- Community: Exposure to heavy metals and VOCs causes eye irritation to chronic conditions like cancer or liver damage. Mold exacerbates respiratory problems, especially in vulnerable populations.

- Personnel: Contractors and cleaning professionals face direct risks from asbestos, lead, and VOCs, including mesothelioma, metal poisoning, and cognitive decline without proper equipment.

Beyond Equipment Challenges

Not all issues can be solved with restoration tools:

- Mental Health: Anxiety, depression, and PTSD affect survivors and first responders after losing homes and lives.

- Displacement: Uninhabitable communities spark housing and economic crises.

- Environmental Damage: Ecosystem burning releases stored carbon and destroys habitats, with effects beyond immediate restoration.

How Mastercraft® Responds

"These hazardous residues—soot, asbestos, VOCs, heavy metals, and more—demand specialized solutions. At Mastercraft USA, we’ve developed tools like Sootmaster® to eliminate soot, Enviromaster® to contain toxic contaminants, and Mastercraft® Engineering to handle dense debris. With fires of the magnitude seen in California, we knew we needed a comprehensive answer: the FR Fire Restoration. Next, we’ll explore how our current lines have laid the groundwork for this innovation."

Mastercraft® Machine Lines: Innovation and Specialization for Professionals

Sootmaster®: Mastering Soot and Ash Removal

The Sootmaster® line is purpose-built to tackle one of a fire’s most persistent and hazardous residues: soot and ash. With Sootmaster® Technology, these machines excel at:

- Soot Capture: Efficiently removes soot, a fine black carbon residue from incomplete combustion of materials like wood, coal, oil, and gas. Its ultrafine particles (PM2.5 and smaller) pose respiratory and reignition risks.

- Cross-Contamination Prevention: Ideal for fire-damaged buildings, HVAC systems, and restoration sites, ensuring soot doesn’t spread to unaffected areas.

-

Risk Reduction: Controls airborne soot deposits that heighten secondary fire risks and degrade indoor air quality.

This line is a must-have for firefighters and contractors needing fast, safe initial cleanup after a blaze.

Enviromaster®: Hazardous Material Containment with HEPA Technology

The Enviromaster® line takes restoration further with Enviromaster® HEPA Technology, designed to contain the most toxic post-fire contaminants. Key features include:

- Critical HEPA Filtration: Captures 99.97% of particles down to 0.3 microns (HOT DOP tested, Type A HEPA, H13-H14 equivalent), ensuring a safe work environment.

- Hazardous Byproduct Management: Built to contain:

- Volatile Organic Compounds (VOCs): Benzene, toluene, and formaldehyde from burnt synthetics, known for toxicity and carcinogenicity.

- Asbestos Fibers: Microscopic particles causing mesothelioma and pulmonary fibrosis, common in fire-damaged older structures.

- Heavy Metals: Lead, mercury, and cadmium dust, posing neurological and cancer risks.

-

Mold Spores: From water-damaged post-fire structures, linked to asthma and allergies.

This line is the go-to for cleaning and restoration pros facing chemical and biological hazards, delivering unmatched safety and efficiency.

Mastercraft® Engineering: Built for Extreme Conditions

The Mastercraft® Engineering line embodies our core heritage: rugged, reliable tools for the toughest environments. Designed for fire restoration, these machines feature:

- Durable Construction: Crafted from cold-rolled steel to withstand harsh fire-damaged sites, from sharp debris to prolonged contaminant exposure.

- Superior Power: Powered by a 1.3 HP By-Pass motor delivering 94 CFM airflow and 84” water lift, ideal for handling dense soot and hazardous particulates.

-

Sealed Airflow System: Prevents leaks, ensuring complete filtration and operator safety under extreme pressure.

These machines are the trusted backbone for contractors and industries needing equipment that endures relentless wear while maintaining peak performance.

A Legacy of Solutions

Each of these lines—Mastercraft®, Sootmaster® and Enviromaster® Engineering—has been a cornerstone in our mission to deliver industry-leading solutions. From soot capture to toxic containment and dense debris handling, our machines have empowered contractors, firefighters, and cleaning professionals to tackle fire restoration’s toughest challenges. Now, with the FR Fire Restoration, we take this legacy to the next level.

Introducing FR Fire Restoration: The Ultimate Fire Damage Solution

The 1510-FR-PRO-HEPA Sootmaster®: Built for Every Fire Phase

Large-scale fires, like those recently in California, create a destruction cycle from initial spread to toxic aftermath. At Mastercraft USA, we knew we needed more than a cleanup tool—we needed a machine to address every stage of this challenge. The 1510-FR-PRO-HEPA Sootmaster® is that solution: the ultimate fire restoration vacuum, blending Sootmaster® soot expertise, Enviromaster® advanced filtration, and Mastercraft® Engineering rugged durability. Here’s how:

-

Start: Soot and Ash Capture

In a fire’s early stages, soot and ash become invisible threats, raising reignition and cross-contamination risks. Built on Sootmaster® technology, the 1510-FR-PRO-HEPA captures these fine carbon particles with precision using the Trap-Sack® Dry Filtration system. Featuring a removable cloth filter and a fully enclosed Infiltrator® synthetic bag, it ensures safe, mess-free disposal—letting contractors and firefighters manage initial risks from the outset. -

During the Fire: Toxic Material Containment

As flames consume structures, they release asbestos, VOCs, heavy metals, and more. Enter Enviromaster® influence with the Critical Sealed True HEPA Filtration System, a hallmark of this machine. Unlike a standard Sootmaster®, it captures 99.97% of particles as small as 0.3 microns—the most penetrating size—via a Type A HEPA filter (H13-H14 equivalent, HOT DOP tested). This means: - Asbestos Fibers: Contained to prevent mesothelioma and fibrosis.

- VOCs like Benzene and Toluene: Removed from the air, cutting cancer and neurological risks.

-

Heavy Metals: Lead, mercury, and cadmium trapped before harming workers.

With rubber gaskets and a sealed airflow design, there’s zero bypass—every ounce of contaminated air is filtered. -

Aftermath: Residue Management and Full Restoration

Post-extinguishment, dense debris, water-induced mold, and lingering chemicals remain. The 1510-FR-PRO-HEPA inherits Mastercraft® Engineering toughness, with a cold-rolled steel tank and head built for the harshest sites. Its Powered by Mastercraft® 1.3 HP motor delivers 94 CFM airflow and 84” water lift, tackling heavy debris to mold spores effortlessly. This quality legacy, sparked by Harry Goldberg in 1946, ensures every part—from 8” wheels to aluminum accessories—is engineered to endure and perform in extreme conditions.

Advanced Filtration & American-Made Durability

Built with rugged commercial-grade construction, the 1510-FR-PRO-HEPA Sootmaster® stands out with:

- Innovative Trap-Sack® Dry Filtration System: Includes:

- A removable cloth filter for efficient debris containment.

- A fully enclosed Infiltrator® synthetic bag, ensuring safe, mess-free soot and ash disposal.

- Cold-Rolled Steel Tank and Head: Engineered to withstand extreme job sites, backed by proven American-made quality standards.

- Mastercraft® High-Performance Motor: Superior power and durability, proudly designed and manufactured in the USA, upholding our industrial excellence commitment.

Why HEPA Filters Are the Heart of FR Fire Restoration

At Mastercraft USA, HEPA filters aren’t an add-on—they’re an obsession. The 1510-FR-PRO-HEPA Sootmaster® elevates Enviromaster® technology to a new benchmark, offering filtration that goes beyond the basics. For professionals, this means:

- Superior Protection: Captures microscopic particles like asbestos, mold, and soot that lesser “HEPA-like” systems miss.

- Compliance and Safety: Its sealed, tested design ensures contractors and emergency teams work risk-free in sensitive sites like hospitals or schools.

-

Air Quality: Raises purity standards, safeguarding workers and affected communities alike.

This isn’t just a vacuum—it’s a containment and purification system redefining fire restoration.

Technical Specifications

- Model: 1510-FR-PRO-HEPA

- Motor: 1.3 HP By-Pass, 120V, Powered by Mastercraft®

- Water Lift: 84”

- Airflow: 94 CFM

- Tank: Cold-Rolled Steel

- Filtration: Critical Sealed True HEPA (99.97% @ 0.3 microns, H13-H14 equivalent)

- Wheels: 2 x 8” + 2 x 2.5” swivel casters

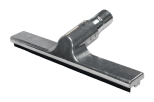

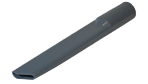

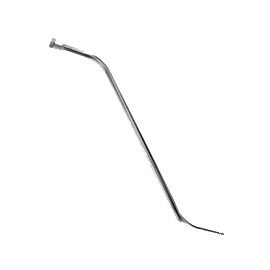

- Accessories: Includes aluminum wand, canvas hose, crevice and floor tools, and more.

Why Choose the 1510-FR-PRO-HEPA Sootmaster®?

This isn’t a generic vacuum—it’s the most powerful, specialized fire restoration tool available. Designed for contractors, hazardous material cleanup teams, and emergency responders, it offers:

- Unmatched filtration and containment for soot, ash, and toxins.

- American-made durability for the toughest environments.

- A 76-year legacy of excellence, now elevated with FR Fire Restoration.

Conclusion: A Legacy Elevated for a Safer Future

"At Mastercraft USA, our commitment to excellence began in 1946 when Harry Goldberg envisioned tools that didn’t just simplify professionals’ work but empowered them to tackle the toughest challenges. For over 76 years, we’ve honored that vision, leading the industry with solutions like Sootmaster®, Enviromaster®, and Mastercraft® Engineering. Today, with the launch of the FR Fire Restoration—the 1510-FR-PRO-HEPA Sootmaster®—we elevate that legacy to new heights.

Massive fires, like those scarring California communities, aren’t just disasters—they’re tests of resilience demanding comprehensive responses. From initial soot threatening reignition to lingering toxic residues like asbestos, VOCs, and heavy metals, the 1510-FR-PRO-HEPA is built to handle it all. With its Trap-Sack® system for ash capture, sealed HEPA filtration removing 99.97% of hazardous particles, and cold-rolled steel construction powered by a Mastercraft® motor, this machine isn’t just a tool—it’s an ally for contractors, firefighters, and cleanup crews on the front lines of recovery.

Made in the USA with quality standards reflecting our heritage, the FR Fire Restoration is more than an innovation—it’s a promise. A promise of safety for the professionals who trust us, protection for the community's rebuilding, and continuity for a tradition of excellence thriving in its fourth generation. Learn more about our story and see how we’ve built this legacy. Ready to lead fire restoration into the future? Get in touch with our team and join the waitlist to be among the first to experience the 1510-FR-PRO-HEPA Sootmaster®—because at Mastercraft USA, we don’t just face today’s challenges; we build tomorrow’s solutions."