Mastercraft® Knowledge Center — FAQ

Clear answers for contractors and facilities.

HEPA & Filtration

What does HEPA 99.97% filtration mean?

It captures 99.97% of particles ≥0.3 microns (mold spores, fine dust, allergens), keeping sensitive areas compliant and cleaner.

What makes a true HEPA vacuum different from a standard vacuum?

True HEPA vacuums use sealed filtration systems that prevent particles from escaping, unlike standard vacuums that may leak dust back into the air.

Why are HEPA vacuums critical for mold and lead abatement projects?

They contain hazardous particles at the source, preventing cross-contamination and helping contractors meet EPA’s RRP Rule and OSHA standards.

How do I know when to replace HEPA filters in an industrial vacuum?

Replace filters when airflow drops, suction decreases, or after heavy use periods. Preventive replacement ensures peak performance.

Why are HEPA vacuums important for mold remediation?

HEPA vacuums are essential for mold remediation because they capture 99.97% of particles as small as 0.3 microns, including mold spores, dust, and allergens. This prevents spores from becoming airborne during cleanup, protecting workers and ensuring compliance with remediation standards. Using a true HEPA-filtered vacuum helps create a safer environment and reduces the risk of cross-contamination.

Learn more about our Enviromaster HEPA Vacuums designed for professional mold remediation.

What’s the difference between a HEPA dry vacuum and a HEPA wet/dry vacuum?

Dry = fine dry debris only. Wet/Dry = liquids + solids with HEPA filtration, ideal for post-flood and construction cleanup.

CTA:

Are Mastercraft HEPA vacuums compliant with OSHA/EPA guidelines?

Yes. Mastercraft HEPA vacuums meet OSHA and EPA requirements for lead and mold remediation projects. They are engineered with sealed filtration systems that maintain proper containment of hazardous particles, helping contractors stay compliant with regulations such as the EPA’s RRP Rule and OSHA standards for worker safety.

Explore our EPA/OSHA-compliant HEPA vacuums for lead and mold abatement.

Flood & Fire Restoration

What makes the Pump Out Flood Vacuum different from a regular wet/dry?

It continuously discharges water while collecting. No stop and dump cycles, so recovery is much faster.

What combination of machines should contractors use after fire and smoke damage?

Combine Sootmaster® for hot ash/soot capture, HEPA units for fine particulates, and Big Red Blower for drying/ventilation. Explore the Fire Damage Restoration Vacuum PRO HEPA which combines Soot Technology and HEPA Filters.

Can a wet/dry vacuum help prevent mold growth after water damage?

Yes. Removing moisture promptly with a wet/dry vacuum reduces the risk of mold growth and speeds up restoration.

How does the Pump Out Flood Vacuum | Mastercraft® help in large-scale flood recovery?

It moves large volumes of water quickly, keeping worksites safe and minimizing damage in flood-affected areas.

How do I control airborne dust during demo/restoration?

Use HEPA vacuums with sealed hoses, work in zones, and ventilate with air movers to maintain air quality.

Sootmaster®

Can the Sootmaster® vacuum be used for hot ash?

No vacuum should be used on actively hot or burning materials. However, Mastercraft® offers the Industrial Ash Vacuum for High-Temp Cooled Residues, designed to handle cooled ash, soot, and fine residues once the material has cooled down. Its heavy-duty tank construction withstands tough environments, including fire-damaged atmospheres and crematory operations.

Explore our Industrial Ash Vacuum for High-Temp Residues | Mastercraft®.

What is the Industrial Ash Vacuum for High-Temp Cooled Residues | Mastercraft® designed for?

It’s built to collect cooled ash and soot in crematories, fire restoration, and other high-temperature environments.

Why is soot and ash collection different from standard dust collection?

Soot and ash require specialized heat-resistant tanks, sealed filtration, and accessories to prevent leaks and damage.

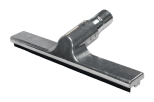

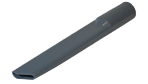

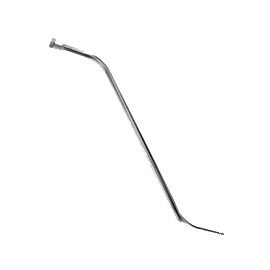

What hose and wand sizes are recommended for soot collection?

Typically 1.25" or 1.5" with heat-resistant accessories for safe, efficient removal.

MAV Series | Air-Compressed

What is the MAV Series (air-compressed machines)?

Pneumatic vacuums powered by compressed air—no electric motor—great for dry-only pickup where electricity is limited.

When should I use a pneumatic vacuum instead of an electric one?

MAV Series pneumatic vacuums are ideal when electricity is not available, unsafe, or restricted. Because they run on compressed air, they are widely used in industrial plants, chemical facilities, refineries, and construction sites where explosion-proof or non-electric equipment is required. They are designed for heavy-duty dry material pickup, including dust, powders, and fine debris, offering a reliable solution for demanding environments.

Explore our MAV Series Pneumatic Vacuums for industrial and hazardous applications.

What industries benefit the most from MAV Series air-compressed vacuums?

Industries like refineries, chemical plants, construction sites, and heavy manufacturing rely on MAV units for dust and dry debris collection without electrical risk.

Are pneumatic vacuums safer in hazardous or explosive environments?

Yes. With no electric motor, pneumatic vacuums minimize ignition risks, making them a safer option in explosive or combustible dust areas.

Big Red Air Blower

When should I use a Big Red Air Blower?

For rapid drying/ventilation after cleaning, floods, or to move air across large or short floor areas.

Can air movers improve safety and air quality on restoration job sites?

Yes. They reduce slip hazards by drying floors faster and help dilute airborne particles, improving worker safety and compliance.

How does the Big Red Air Blower speed up flood and fire restoration?

By moving high volumes of air across wet or smoke-damaged surfaces, it accelerates drying and helps restore air quality quickly.

Pristal® Floor Finish Applicators

What surfaces work best with Pristal applicators?

Large, smooth floor areas for even finish application with reduced lap marks.

How do I avoid streaks when applying finish?

Clean surface, control moisture, maintain steady pace, and use fresh pads per manufacturer guidance.

What’s the advantage of using a Pristal® applicator over traditional mop-and-bucket methods?

Pristal® applicators apply finish evenly and quickly over large areas, reducing labor and eliminating streaks common with mops.

How do contractors achieve a streak-free finish on large floors?

Use clean applicator pads, apply steady pressure, and work in smooth passes on prepared surfaces. This ensures a uniform, professional finish.

Wide Area Vacuum Cleaner

Can a Wide Area Vacuum clean both carpet and hard floors in large facilities?

Yes. Use the proper height/brush settings per surface for best pickup.

When should I choose a Wide Area Vacuum instead of a standard commercial vacuum?

For large, open facilities (schools, airports, warehouses) where coverage and productivity matter.

Is there a cordless option for the Wide Area Vacuum?

Yes. Mastercraft® offers a Cordless Wide Area Vacuum that delivers the same wide-path cleaning efficiency without being restricted by power cords. This makes it ideal for large facilities such as airports, schools, and convention centers where mobility and productivity are key.